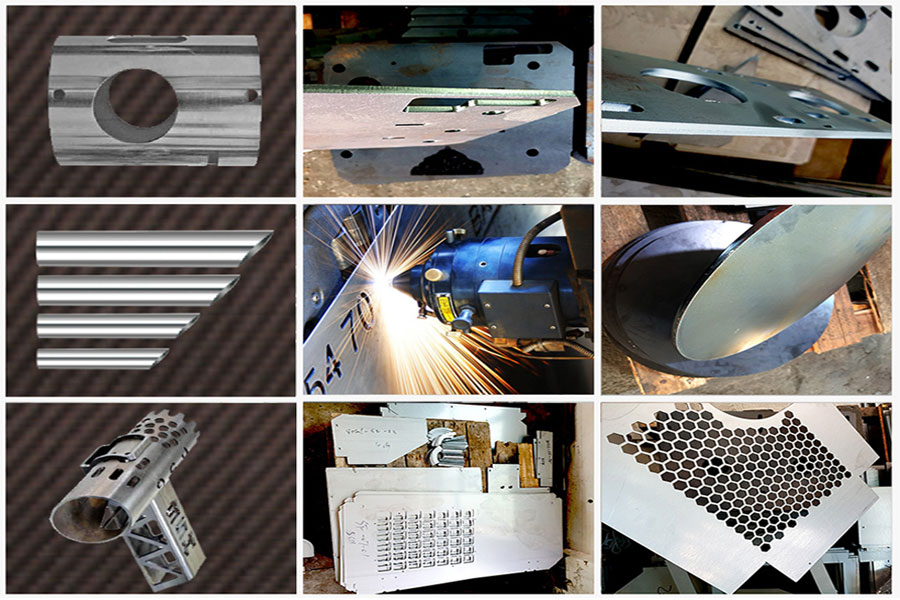

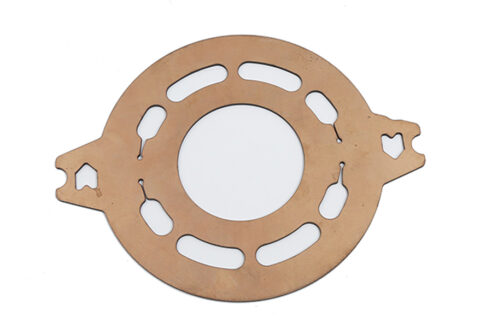

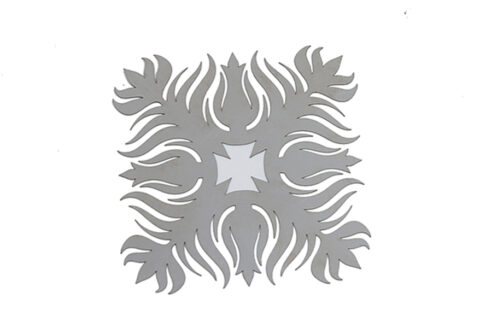

Hollow Disc Laser Cutting

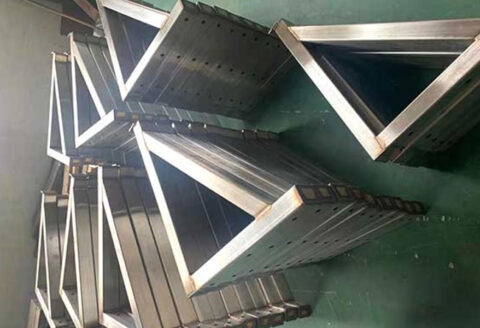

ISO 9001:2015 certified. 3-axis Hollow Disc Laser Cutting services of OEM parts. Works with stainless steel, thin metal, heavy plate, Inconel® and Monel®. Capable of handling sheets and plates with 16 gauge to 1.25 in. thickness, 20 to 90 ft. length and 7 to 12 ft. width. Other capabilities include fabrication, press brake forming, bending, contract manufacturing, punching and welding. Additional services such as metal finishing, mechanical beveling, painting, galvanizing, kitting and packaging also provided. Available in prototype to production runs. Suitable for lifting equipment, truck crane, wear part, boom component and frame rail applications. Serves the agriculture, aerospace, construction, mining, military and defense industries. AWS D1.1 certified.

| Material | Aluminum 6061, 6063, Stainless Steel, Iron, brass |

| Processing Craft | Drawings→ mould making → stamping →rough machining → CNC machining (if need) →surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Inspection |

1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. 2.Third Party inspection available upon requirement. |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Quality Guarantee | 3 years |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm.

2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance, smooth surface roughness is Ra3.2 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. |

Categories: Plate Laser Cutting