A hypotube is a thin metal tube used in many modern medical treatments. Fully automated workstation laser processing is one of the preferred methods for manufacturing such precision medical products, ensuring the necessary precision, throughput and throughput. With application-optimized software, the process can be made simple and very efficient.

Minimally invasive surgery has many advantages, and in many of these procedures a key device is the use of a hypotube (sometimes called a guidewire). These hypotubes need to be small and flexible to enter human blood vessels. And they need to be hollow to control tools or deliver drugs.

Hypotubes: A Life-Saving Technology

Hypotubes must meet many complex requirements. Its edges must be free of burrs and the material it contains should be soft and easily sterilizable. The distal design can range from a simple incision to a complex micromachined component. To operate reliably, the hypotube should be flexible when subjected to a certain amount of torque and must be able to withstand kinking and pushing.

Metal hypotubes gain flexibility through a pattern of cuts in their tube walls. Interrupted spiral patterns are one way to achieve flexibility. The cut length and cut spacing determine the residual stiffness of the tube.

Precise And Efficient Machining Of Hypotubes

Typically, hypotubes are processed using advanced laser technology. Laser systems have to perform different tasks such as marking, cutting and drilling on or in the walls of metal pipes. Currently, medium-power fiber lasers are mainly used to perform these tasks. All edges must be free of burrs, which may require some post-processing after laser processing.

However, more and more users are now choosing femtosecond lasers over fiber lasers. This ultrashort pulse (USP) laser rapidly accumulates its energy into the material, preventing heat from diffusing and minimizing the heat-affected zone as the material evaporates. Therefore, USP lasers are capable of producing relatively smooth edges, and post-process water cleaning is usually sufficient. But conversely, USP lasers, while very accurate, are somewhat slower than fiber lasers.

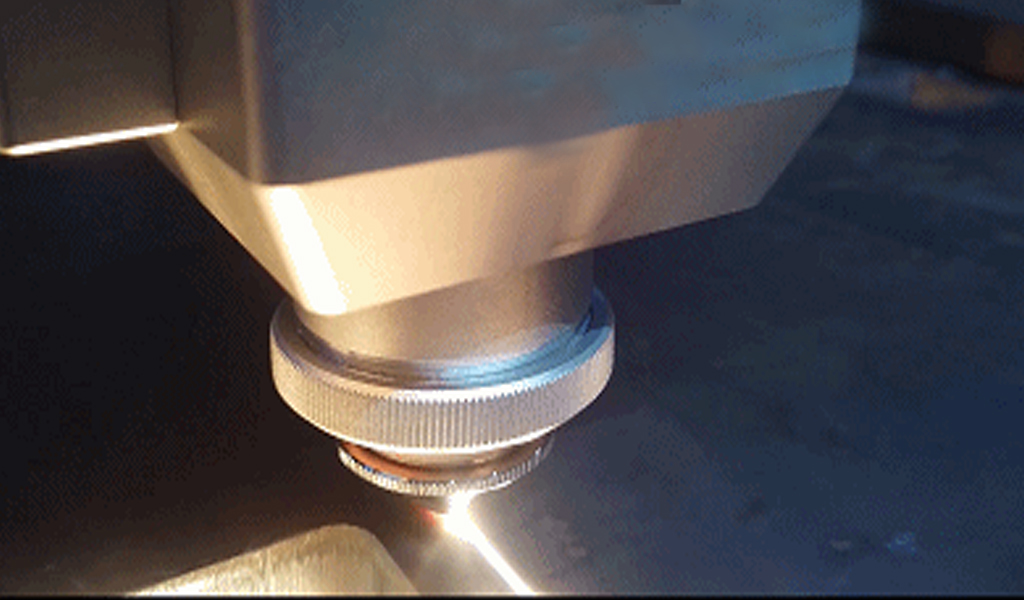

Figure 1 shows a hypotube laser cutting using Be-Cu. For demonstration purposes, a StarCut Tube Hybrid with both a fiber laser and a femtosecond laser was used. Equipped with only a fiber laser or a femtosecond laser, the StarCut Tube SL can also do the job while taking up less space.

The samples were cut from stainless steel tubes with an outer diameter of 0.7 mm. The tube has a wall thickness of 100 µm.

A section called the paring is cut off at the left end. A small test incision was made within the peel. In addition, the hypotube is marked with two black rings. All three steps are performed using a Monaco femtosecond laser.

Next, a long, interrupted spiral is carved into the tube wall. For this process, the system switched to the hybrid station’s second laser source: the moderately powerful Be-Cu StarFiber. The spiral pattern is cut “on the fly,” that is, while the tube is constantly moving at high speed. In this process, the laser timing is precisely triggered at the start of each cut.

Figure 2 shows the effect of fiber laser processing. There are two typical styles of hypotube shafts: the interrupted spiral or the so-called brickwork style. The bricklaying pattern consists of parallel interrupted cuts, similar to stone in a brick wall. A typical hypotube is approximately 1.5 m long, and longer sections of the hypotube can be processed very quickly using a dynamic cutting procedure. The cycle time for this sample was only 35 s.

Easy-To-Use Dynamic Laser Cutting Software

Be-Cu’s user interface was developed for easy processing of low-volume and high-volume medical device products. Cagila software is optimized for easy programming of handlers. To speed up the workflow, some additional features are integrated, such as a strobe function. This feature enables automatic generation of interrupted spiral designs or brickwork patterns during the pipe cutting process.

The trigger signal output is generated synchronously with the position of the rotary axis. As a result, the laser’s switching command latency and jitter are reduced to very low levels. The geometry of a spiral or brickwork design can be generated using table-based input or from imported CAD data and can then be machined automatically. Post-processing features can also be incorporated, such as automatic re-clamping after a defined distance and the addition of additional bends after the start or before the final cut-off position.

Automated Laser Cut That Takes Up Little Space

Medical devices are often manufactured in expensive clean rooms. Be-Cu SL occupies less space than similar laser machines, minimizing the use of valuable clean room space.

Be-Cu can be configured for manual and automated processing, and can be equipped with fiber lasers, femtosecond lasers, or both. Multiple feeder and unloader modules can be added for a fully automated solution. For example, the machine can use StarFeed S to automatically load tubing such as thrombectomy catheters with outer diameters as small as 0.3 mm. Additional tube loading modules accommodate tubes with diameters from 1 to 20 mm and lengths of 3 m, allowing fully automated production without any manual operations.

Be-Cu can use the StarFiber laser, which has an adjustable pulse width of 10 to 50 µs, or the very advanced USP laser Monaco, which has a pulse width of less than 350 fs. Fiber lasers are ideal for cutting thicker materials and pipes, where speed is important. Femtosecond lasers are better suited for cutting extremely thin parts or precision parts where surface finish is important and thermal side effects must be avoided.

The machine can handle both tubular substrates (up to 30 mm in diameter) and flat substrates, making it even more practical and valuable. The machine can perform 2-, 3- or 4-axis operations.

The software is optimized for ease of operation and allows for fast processing. Different operators can have different access rights based on their proficiency. Process and workpiece parameters can be recorded for traceability. In a hybrid system, the machine can switch between two lasers on the same job using one CNC file. For fully automated machining, there is a dedicated module for automatic texting; it sends an SMS to the operator every time a problem occurs or when a job is completed.

Be-Cu can improve processing flexibility to a great extent and takes up little space. Where required, high precision and throughput can be achieved by using versatile software and mechanically integrating different laser sources. The machine is designed for automated production of low- and high-volume medical device parts and is available with automatic feeding and unloading options.

Customers can benefit from this experience in different ways. For example, they can send samples for testing and process development. We also provide regular training to operators of all skill levels to share expertise.