Laser Cutting Round Tube

With the rapid growth of stainless steel tube production and consumption in China, laser tube cutting equipment is rapidly popularized in China, the demand for CNC tube cutting talents and laser tube cutting technology are developing rapidly, which highlights the current serious shortage of laser tubes and backward cutting equipment and CNC pipe cutting talents and technology. This is also reflected in the fact that some stainless steel companies have advanced laser cutting equipment, but there are still some problems that expose the low efficiency of pipe cutting and poor cutting quality, resulting in serious waste of pipe materials.

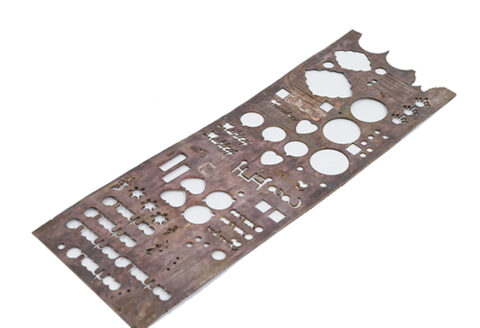

Laser cutting pipe processing technology is a technology with high production efficiency and strong production capacity. At the same time, as long as the design plan can be modified in one minute without affecting the entire product production process, the greater advantage is that the end user can control the short-term version or the mid-term production version, instead of manufacturing a large number of templates, and can respond to customers’ requests more quickly. Demand, so there is no mold needed. From the perspective of flexibility, the laser tube cutting technology can process any programmed shape, and the laser can complete the cutting in any direction. The shape of the template can be changed quickly without the help of any tools, which makes it possible to process competitive personalized packaging or trademarks. Accuracy is also one of the advantages of digital systems. Laser processing can make up for errors in printing and post-printing processes. For example, the material may be stretched and deformed, and the laser can be adjusted according to these deformations, while the traditional template making cannot. Laser tube cutting product processing is a high-level technology. Of course, it also requires a certain cost investment in the early stage. The following provides targeted solutions for laser tube cutting related problems.

Use professional tube cutting and nesting software on the computer to pre-program the drawings, nesting and blanking sections to generate the cutting program, and then perform full-stroke automatic laser cutting and blanking of large-length stainless steel pipes. Due to the high cutting efficiency and the complicated programming and layout, if used improperly, the pipe will be wasted and the cutting efficiency will be reduced. Professional pipe arrangement software is the basis and prerequisite for large-scale, high-efficiency and high-quality cutting and production of CNC pipe cutting machines.

At present, there are some quality problems in the process of laser tube cutting, such as: burning cutting part, cutting the pipe surface at the corner of the burning part, and deforming or failing to close when cutting the round part, which directly leads to serious waste of pipe and cutting. The production efficiency of the tube is low. Numerical control pipe cutting technology is to provide advanced pipe cutting technology and rich pipe cutting experience in the pipe cutting control software of the numerical control system, so that pipe cutting operators can achieve high-quality and high-efficiency CNC cutting through the proficient use of the control system. CNC laser cutting pipe technology is a mass production, high efficiency, high quality pipe cutting production method.

Categories: Tube Laser Cutting