Welding Processing Of Special Shaped Parts

The main processes of stainless steel special-shaped plate processing include shearing, bending, bending forming, welding, riveting, table top, surface processing and so on. Laser cutting manufacturers analyze the processing steps of sheet metal parts for you as follows:

- Design sheet metal parts drawings, construct detailed sheet metal parts structure, and draw unfolded drawings, that is, unfolded drawings of complex structural parts;

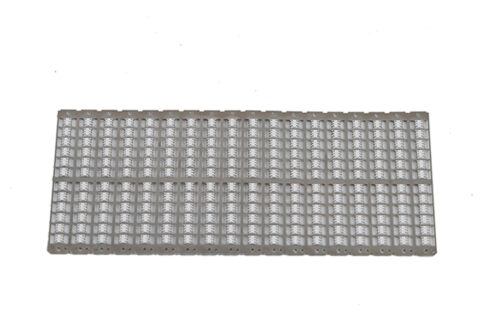

- Cutting: There are many cutting methods, usually a combination.Use a shearing machine to cut and open the drawing, that is, the shape, length, and width of the sheet metal parts required, and punch with a punch and die;The punching time is short and the efficiency is high. The punch is used to press the flat structure of the unfolded part on the top of the sheet metal step by step CNC, blanking, press NC programming. In addition, there is laser cutting.

- Flanging and tapping: Flanging is broaching, which is to process a small base hole into a slightly larger hole to improve strength and prevent tooth slippage. It is usually used for sheet metal processing.

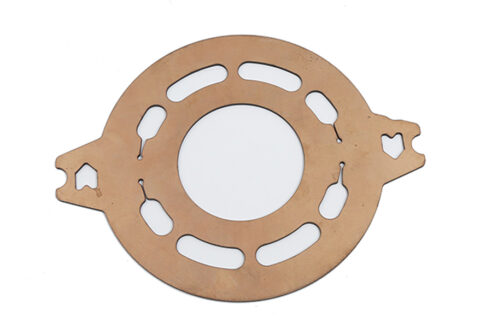

- Punching processing: Punching processing is completed by corresponding mold operations, such as: punching bevel, punching blanking, punching convex shell and other processing methods.

- Stamping riveting: use punch or riveting machine to complete the operation, such as riveting studs, riveting nuts, riveting screws, etc.

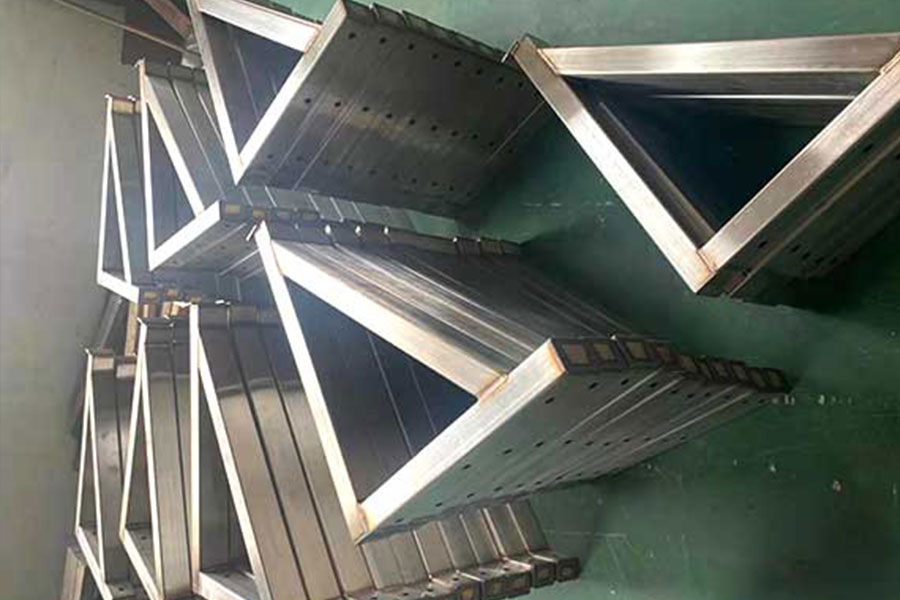

- Bending processing: usually through the combination of bending equipment and bending molds, the plane material is made into a three-dimensional shape.

- Welding process: Welding refers to the combination of multiple parts. Generally there are robot welding, carbon dioxide gas shielded welding, argon arc welding, spot welding, etc., which can be selected according to needs.

- Surface treatment: usually used to protect materials and prevent oxidation. The surface of the material is coated with a protective film, such as phosphating film, baking paint, etc.

- Assembly: Assemble multiple parts into a finished product in a certain way.

Categories: Welding Processing