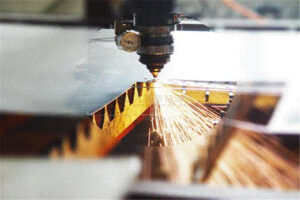

Laser cutting samples

1. The cutting focus is above the surface of the workpiece:

This method is also called negative focal length, because the cutting point is not located on the surface of the cutting material or inside the cutting material, but is located above the material we want to cut. This method is mainly used for cutting materials with relatively high thickness. The reason why the focus is positioned above the cutting material in this way is mainly because the thick plate requires a large cutting width, otherwise the oxygen delivered by the nozzle is very likely to be insufficient and cause the cutting temperature to drop. But one disadvantage of this method is that the cutting surface is relatively rough, which is not practical for high-precision cutting.

2. The cutting focus is on the surface of the workpiece:

This method is also called zero focal length. It is generally common in the cutting of workpieces such as carbon steel plates. When used, the focus of the laser cutting machine is selected close to the surface of the workpiece. In this mode, the upper and lower surfaces of the workpiece are different in smoothness. Generally speaking, The cutting surface close to the focal point is relatively smooth, while the lower surface away from the cutting focal point appears rough. This mode should be determined according to the process requirements of the upper surface and the lower surface in the actual application.

3. The cutting focus is below the surface of the workpiece:

This method is also called positive focal length. When the workpiece you need to cut is stainless steel or aluminum steel plate, the mode that the cutting point is inside the workpiece is often used. However, a disadvantage of this method is that due to the focus principle, the cutting width is relatively larger than the cutting point on the surface of the workpiece. At the same time, the cutting airflow required in this mode is large, the temperature is sufficient, and the cutting and piercing time is slightly longer. So when you choose the material of the workpiece is mainly stainless steel or aluminum with high hardness.