Don’t be unfamiliar with the grid structure. Many buildings and furniture are made of steel materials. Compared with traditional building materials, it has the characteristics of light weight, high hardness and good stability. It is one of the main types of building structures. The processing of grid structure is a complex and comprehensive technology. The following describes the manufacturing process of the grid structure;

1. Sample preparation rod and sample preparation board: The sample preparation board can be made of iron sheet or plastic board, and the thickness is 0.50~0.75mm. The sample rod is generally made of iron sheet or flat iron, and a wooden ruler rod can be used when the length is short. The sample rod and sample plate should be marked with job number, drawing number, part number, quantity, processing edge, slot position, bending line, bending direction, aperture, and fillet radius. Sample sticks and sample plates should be kept properly until the end of the project.

2. Marking materials: check the specifications, materials, and batch numbers of the steel, and remove the oil, dirt and stolen goods on the surface of the steel plate. There are four marking methods: centralized marking method, nesting method, statistical calculation method and unified marking method for remaining materials.

3. Marking: Marking with processing drawings, sample bars, samples, and steel strips. At present, some advanced grid structure processing plants adopt program-controlled automatic marking machines, which are not only efficient, but also accurate, and save materials.

4. Cutting: Mesh structure cutting includes high temperature heat sources such as gas cutting and plasma laser cutting china, as well as the use of mechanical forces such as shearing, cutting, and frictional heat. The cutting ability, cutting accuracy, cutting section quality and economy should be considered.

5. Edge processing and end processing: The main methods are: shoveling, planing, milling, carbon arc gouging, gas laser cutting, and bevel processing.

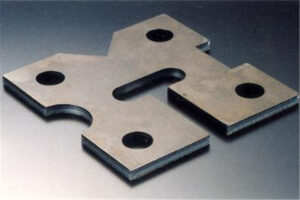

6. Punching: In the welding structure, welding will inevitably cause shrinkage and deformation, so in the production process, the accuracy of the product will be greatly affected when the hole is opened. Especially for columns and beams, the dimensional accuracy of the hole group directly affects the accuracy of the grid structure installation, so it is very important to grasp the opening time.

7. Assembly: The assembly methods of the grid structure include prototype method, copy assembly method, vertical assembly method, horizontal assembly method and tire mold assembly method.

8. Welding: It is a key link in the production of grid structure.

9. Friction surface treatment: The anti-slip coefficient of the friction surface of the high-strength bolt after treatment should meet the design requirements (generally 0.45~0.55). The friction surface can be treated by sandblasting, shot blasting, pickling, grinding wheel and other methods. Generally, it should be carried out according to design requirements. If there are no design requirements, the construction unit may adopt appropriate construction methods.

10. Coating, number: The ambient temperature of the coating should meet the requirements of the coating product manual. If not specified, the ambient temperature should be between 5~38℃, the relative humidity should not be greater than 85%, and there should be no condensation and oil stains on the surface of the module. Rainproof treatment should be done within 4h after painting. After painting, the parts should be numbered according to the design drawings, and the numbering position should conform to the principles of easy stacking, easy installation, and easy inspection. For large or important parts, the weight, center of gravity, hoisting position, positioning mark, etc. should also be marked. The number summary data can be unified with the transportation documents, construction organization design documents, quality inspection documents, etc., and the number can be re-sprayed after the completion and acceptance.