Light guide focusing system

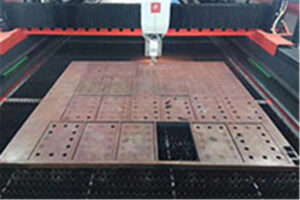

In laser cutting equipment, the role of the light guide system is to guide the light beam output by the laser generator to the cutting head that focuses the light path. For laser cutting tubes, in order to obtain high-quality slits, the focused spot diameter and power of the focused beam are small, which makes the laser generator output low-order modes.

In order to obtain a smaller beam focus diameter, the lateral mode of the laser is smaller, preferably the fundamental mode. The cutting head for laser cutting of stainless steel plate has a focusing lens. After the laser beam is focused by the lens, a smaller focus spot can be obtained, so that high-quality pipe cutting can be carried out.

Control of cutting head trajectory

In pipe cutting, the processed pipe belongs to the space surface and has a complex shape. If it is difficult to program and process with conventional methods, the operator is required to select the correct processing path and appropriate reference point according to the requirements of the processing technology. Record the feed status of each axis and the coordinate value of the reference point through the CNC system. Then, use the space straight line and arc interpolation function of the laser cutting system to record the coordinate value of the processing process and generate the processing program. Therefore, the research on the automatic vertical function of laser and cutting tube is also one of the important technical contents of laser cutting.

Automatically control the focus position during laser cutting

In order to ensure the cutting quality of the laser cutting tube, the vertical direction of the focus relative to the surface of the workpiece can be kept constant through the automatic measurement and control device, which is the key to the laser cutting china tube. Currently, we control the laser focus position and the spool of the laser processing system

The integration of X-Y-Z makes the movement of the laser cutting head more light and flexible, and the position of the focus can be known as much as possible, so as to avoid collisions between the cutting head and the cutting tube or other objects during the processing.

Influence of main process parameters

Laser cutting pipes are widely used in industrial society. The pipes being cut are becoming more and more diverse, and the pipe parts have their own complexity. Therefore, according to the material, shape and processing requirements of the cutting tube, selecting the appropriate laser cutting process parameters to obtain cutting efficiency and cutting quality has become a concern for all laser cutting system users.

(1) The influence of laser power.

For laser generators that output continuous waves, laser power has an important influence on laser cutting. In theory, the higher the laser power of the laser cutting pipeline equipment, the higher the cutting speed can be obtained, but combined with the characteristics of the pipeline itself, a large cutting power is not a good choice. When the cutting power increases, the laser mode changes, which will affect the focus of the laser beam. In actual processing, we often choose the power density obtained when the power is less than the power, so as to ensure the efficiency and cutting quality of the entire laser cutting.

(2) The influence of cutting speed.

When laser cutting pipes, you must ensure that the cutting speed is within a certain range to obtain better cutting quality. If the cutting speed is slow, excessive heat will accumulate on the pipe surface, the heat affected area will become larger, the cutting seam will be widened, and the discharged hot melt will burn the cutting surface and make the cutting surface rough. When the cutting speed increases, the smaller the average width of the pipe circumference, and the smaller the pipe diameter, the more obvious the impact. As the cutting speed increases, the laser action time is shortened, the total energy absorbed by the pipe decreases, the temperature at the front end of the pipe decreases, and the width of the cutting joint decreases. If the cutting speed is too fast, the pipe cutting will not penetrate or cut continuously, which will affect the overall cutting quality.

(3) The influence of pipe diameter.

When laser cutting pipes, the characteristics of the pipe itself will also have a great impact on the processing process. For example, the size of the pipe diameter has a significant impact on the processing quality. Through the research of laser cutting thin-walled seamless steel pipes, it is found that under the condition of constant process parameters, the laser cutting pipe equipment will continuously increase the width of the cutting joint.CNC Machining Blog About Cnc Machining Industry – PTJ Manufacturing Shop

(4) The type and pressure of auxiliary gas.

When cutting non-metal and some metal pipes, compressed air or inert gas (such as nitrogen) can be used as auxiliary gas, and most metal pipes can use active gas (such as oxygen). After the auxiliary gas type is determined, the determination of the auxiliary gas pressure is very important. When cutting pipes with small wall thickness at high speed, the auxiliary gas pressure should be increased to prevent slagging during cutting; when the pipe wall thickness is large or the cutting speed is slow, the auxiliary gas pressure should be appropriately reduced to prevent pipe cutting or Continuous cutting.

When laser cutting pipes, the position of the beam focus is also very important. When cutting, the focus position is generally on the surface of the cutting tube. When the focus is in a better position, the cutting seam is small, the cutting efficiency is high, and the cutting effect is good. In most cases, the beam focus is adjusted below the nozzle, and the distance between the nozzle and the pipe surface is about 1.5mm. At the same time, factors such as laser pulse waveform and light output mode also have a certain impact on the cutting effect.