Nowadays, laser cutting processing can not only provide processing services for various products with very high precision requirements, but also provide batch product processing, etc., because we all know that laser cutting products are fast and good in quality, no matter in which environment The lower processing and cutting of the plate can guarantee the product quality, and also provide a good operating environment for the operators of the manufacturer. The emergence of this kind of processing has replaced part of the mechanical processing and has become an “important role” in the processing industry.

Wonder metal has been in the precision sheet metal industry for many years and has rich industry experience. Looking for Wonder Metal for laser cutting processing, you can rest assured and reliable! One-stop service from equipment shell processing to laser cutting processing!

Laser cutting processing

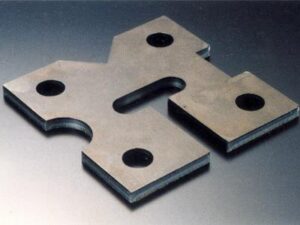

Laser cutting is now widely used by people in a variety of different processing industries. No matter which industry it is, laser cutting methods can be used to process materials. The current processing industry uses this method to provide cutting or hollowing processing of stainless steel plates, etc., regardless of whether the stainless steel plate is thin or thick, it can provide processing. Although stainless steel thick plates can also be processed, the thickness of the plates is also certain. Required, if the sheet is too thick, it may not be able to provide cutting processing.

Laser cutting processing can undertake laser cutting processing services for various materials. Now laser cutting china can not only provide processing services for stainless steel plates of different thicknesses, but also provide processing services for metal plates of other materials, as well as non-metallic materials such as acrylic. Processing. The quality of the products processed by laser cutting is good, the speed is fast, and the processing time is shortened.

Nowadays, laser cutting processing can not only provide processing services for various products with very high precision requirements, but also provide batch product processing, etc., because we all know that laser cutting products are fast and good in quality, no matter in which environment The lower processing and cutting of the plate can guarantee the product quality, and also provide a good operating environment for the operators of the manufacturer. The emergence of this kind of processing has replaced part of the medical machining and has become an “important role” in the processing industry.

Wonder metal has been in the precision sheet metal industry for many years and has rich industry experience. Looking for Wonder Metal for laser cutting processing, you can rest assured and reliable! One-stop service from equipment shell processing to laser cutting processing!

Laser cutting processing

Laser cutting is now widely used by people in a variety of different processing industries. No matter which industry it is, laser cutting methods can be used to process materials. The current processing industry uses this method to provide cutting or hollowing processing of stainless steel plates, etc., regardless of whether the stainless steel plate is thin or thick, it can provide processing. Although stainless steel thick plates can also be processed, the thickness of the plates is also certain. Required, if the sheet is too thick, it may not be able to provide cutting processing.

Laser cutting processing can undertake laser cutting processing services for various materials. Now laser cutting can not only provide processing services for stainless steel plates of different thicknesses, but also provide processing services for metal plates of other materials, as well as non-metallic materials such as acrylic. Processing. The quality of the products processed by laser cutting is good, the speed is fast, and the processing time is shortened.