As the global manufacturing industry develops in the direction of refinement, intelligence and customization, lasers are widely used in industrial manufacturing, biomedical, military and other fields due to their good monochromaticity, directionality, brightness and other characteristics. global industrial chain. As the division of labor in the laser industry continues to mature, the application of lasers in the field of micromachining is becoming more and more extensive. In daily life, laser micromachining technology can be seen everywhere, electronic product marking, electrical appliance shell marking, food and drug production date marking, consumer electronics micromachining, cutting and welding of mobile phone metal shells are all used in laser micromachining technology. In addition, Laser processing is also used in PCB/FPCB board cutting and sub-board, ceramic punching and scribing, glass, sapphire, wafer cutting and micro punching and other fields.

Six Major Processes In The Field Of Laser Micromachining

Laser processing is an industrial application of laser technology. A certain power of laser is focused on the object to be processed, so that the laser interacts with the object to heat, melt or vaporize the processed material to achieve the purpose of processing. At present, micromachining applications in the laser manufacturing industry mainly include laser cutting, laser marking, laser welding, laser engraving, surface treatment, and laser 3D printing. The six major processes in the field of laser micromachining are introduced below.

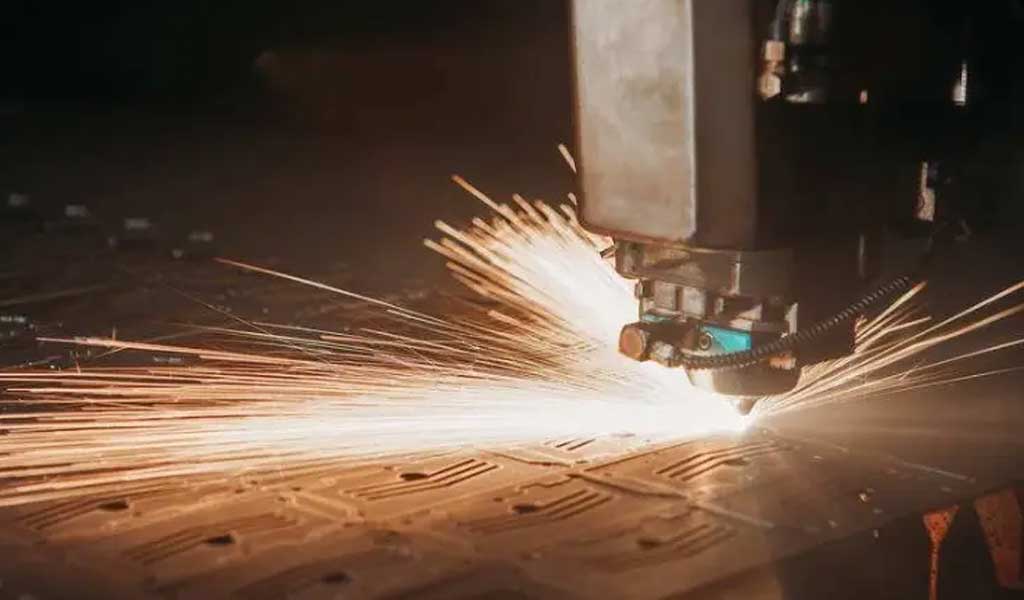

①Laser cutting

Principle: The workpiece is irradiated with a focused high-power density laser beam to rapidly melt, vaporize, ablate or reach the ignition point of the irradiated material, and at the same time, the molten material is blown away by the high-speed airflow coaxial with the beam, thereby laser cutting the workpiece.

Features: fast cutting speed, smooth and beautiful surface, one-time processing, small deformation of workpiece, no tool wear, low cleaning pollution, can process metal, non-metal and non-metal composite materials, leather, wood, fiber, etc., suitable for thickness of automobile body Fine processing of sealed devices such as boards, auto parts, lithium batteries, pacemakers, sealed relays, and various devices that do not allow welding contamination and deformation.

②Laser marking

Principle: The workpiece is partially irradiated with a high-energy-density laser to vaporize the surface material or undergo a chemical reaction of color change, thereby leaving a permanent mark.

Features: It belongs to non-contact processing, can be marked on any special-shaped surface, the workpiece will not deform and generate internal stress, high processing accuracy, fast processing speed, clean and environmentally friendly, low cost, suitable for metal, plastic, glass, ceramics, wood , leather and other materials marking.

③ Laser welding

Principle: The surface of the workpiece is heated by high-energy-density laser beam radiation, and the surface heat diffuses to the interior through thermal conduction. By controlling the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool.

Features: less weldability, not affected by magnetic fields, small space restrictions, no electrode pollution, suitable for automatic high-speed welding, can weld metals with different properties, can work in closed spaces, suitable for circular saw blades, acrylic, Spring gaskets, copper plates for electronic parts, some metal mesh plates, iron plates, steel plates, phosphor bronze, bakelite, thin aluminum alloys, quartz glass, silicone rubber, alumina ceramic sheets under 1mm, titanium alloys used in the aerospace industry, etc.

④Laser engraving

Principle: The laser irradiates the surface of the material, and the material instantly melts or vaporizes after absorbing energy to form a scribed line.

Features: automatic number jumping, small heat-affected area, fine lines, cleaning and wear resistance, environmental protection and energy saving, material saving, can be used for wood products, plexiglass, metal plates, glass, stone, crystal, paper, two-color plate, alumina , leather, resin and other materials etching.

⑤Surface treatment

Principle: Use laser to heat the surface of metal material to achieve surface heat treatment.

Features: fast processing speed, small deformation of parts, precise processing, and automatic quenching treatment effect, suitable for heat treatment of auto parts such as cylinder liners, crankshafts, piston rings, commutators, gears, etc. There are also a wide range of applications in the field.

⑥Laser 3D printing

Principle: A layer of powder is spread on the surface of the workpiece by a powder spreading roller, and the laser beam scans the powder layer according to the contour section of the powder layer, so that the powder is melted and then sintered to realize the bonding of the workpiece.

Features: simple processing technology, wide range of machinable materials, high processing precision, no need for support structure, material utilization

High rate, combined with computer numerical control technology and flexible manufacturing technology, can be used for mold and model 3d printing manufacturing.

Development of Laser Micromachining Applications

At present, the market share of domestic fiber lasers is higher than that of solid-state lasers. The main reason is that fiber lasers are mainly used for high-power macro processing, and the market demand is consistent with the development stage of domestic manufacturing; solid-state lasers are mainly used for micro-processing, although the micro-processing market is developing rapidly. However, the current market capacity is smaller than the macro processing market capacity, but high-precision manufacturing such as wearable devices, semiconductor chips, medical care, and new energy is still a key national support project.

Although various types of lasers focus on different industrial applications, and the market demand for downstream applications is quite different, there are certain differences in their market sizes. However, as the global industrial laser market continues to grow, micromachining applications will continue to increase in the industrial and consumer fields in the future.