Method to solve casting porosity First analyze the reasons for the formation of stomata, and then take corresponding measures.

Advanced laser technology a weapon to improve the level of automobile manufacturing

In recent years, with the continuous progress of science and technology, advanced manufacturing technology represented by laser technology is continuously promoting the upgrading and innovation of the automobile manufacturing industry, and its application in automobile processing has become more and more extensive. Compared with traditional manufacturing technology, laser technology has many advantages such as non-contact processing, high precision, high flexibility, Read more

The diversity of CNC prototype model processing methods?

The diversity of CNC prototype model processing methods? Do you know the CNC prototype model? The following Pingte precision hardware parts processors will explain to you! With the gradual growth of the prototype industry, the manufacturing process has also been updated day by day. There are 3D printing and silica gel casting. But CNC machining is still the most common Read more

Common metal forming process

Die-cutting process-knife die cutting process, the film panel or circuit is positioned on the bottom plate, the knife die is fixed to the template on the machine, and the force provided by the machine’s downward pressure is used to control the blade to cut the material. The difference between him and the punching die is that the cut is smoother; Read more

The basic principle of spray processing for fault diagnosis

Powder spraying: the process flow and advantages and disadvantages of electrostatic spraying

How to re-fuse during thermal spray processing

In the process of thermal spraying, the coating is a discontinuous structure formed by the molten state of thermal spraying powder particles sprayed to the substrate through high-pressure air at high speed, layer by layer very regularly superimposed, and the workpiece substrate undergoes processes such as bumping, deformation and solidification. Afterwards, a thermal spray processing coating is formed.

What are the ways to distinguish the quality of thermal spray coatings?

What should be paid attention to in the process of painting

Painting processing is a messy project. There are many precautions. The surface painting of rubber products prevents dust pollution. If conditions permit, independent air supply and exhaust equipment should be selected for the entire painting production line to ensure clean air throughout the laser cutting.

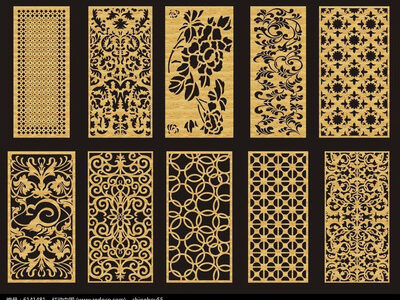

The influence of beam parameters and workpiece characteristics on quality

The quality of laser cutting processing is recognized, both in accuracy and cutting surface are much better than many other cutting methods. Therefore, customers have begun to turn to this cutting method with high speed and good effect. However, many people find that some manufacturers have particularly good cutting quality for the same products processed by laser cutting, and some Read more