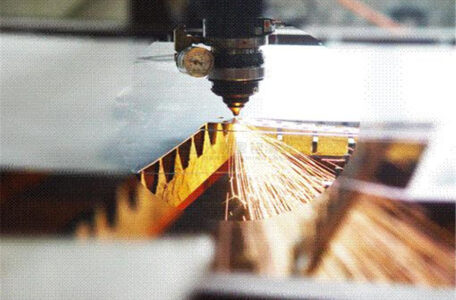

Laser cutting is a thermal cutting method that uses a focused laser beam as the main heat source.

Laser cutting machine and traditional CNC equipment in sheet metal processing

With the application of laser cutting machines, sheet metal processing technology has been developed rapidly, and has brought a revolutionary concept to sheet metal processing. As a traditional sheet metal cutting equipment, mainly numerical control equipment, including shears, punches, flame cutting, https://aluminum-reflector.complasma cutting, high-pressure water cutting, etc., what are the advantages of laser cutting machines compared to it? Let us Read more

The difference between laser cutting and traditional processing technology

Flame cutting is the original traditional cutting method due to its low investment. In the past, the requirements for processing quality were not high. When the requirements are too high, a machining process can be added to solve the problem, and the market is very large. Now it is mainly used to cut thick steel plates over 40mm. Its disadvantage Read more

Focus adjustment and cut surface flatness of laser cutting equipment

Wonder metal laser cutting process is actually relatively safe

Several important factors affecting the accuracy of laser cutting

Common sense that you must know when doing sheet metal processing

Common sense that you must know when doing sheet metal processingAfter the drawing is received, choose different blanking methods according to the different opening drawings and batches, including laser, CNC punching, shearing, molds, etc., and then make the corresponding opening according to the drawing. Place the worktable next to the CNC and the laser cutting, which is conducive to placing Read more

Influencing factors and effect measurement of laser cutting

Influencing factors and effect measurement of laser cuttingIn the laser processing equipment market, laser cutting processing is the most important application technology. In 2015, my country sold about 3,000 laser cutting machines. The substitution effect of laser cutting machines on shears and punches has become more and more obvious. After the more popular laser marking application in the market, it Read more

Briefly introduce how the process parameters of wonder metal laser cutting are formed

In wonder metal laser cutting processing technology, we often need to pay special attention to the cutting speed, thickness and its slit width. First of all, regarding the speed of wonder metal laser cutting, the speed will increase when the power of the laser and the pressure of the jet increase, but the speed will decrease as the thickness of Read more

What are the steps involved in wonder metal sheet metal processing?

In the current production operations, what are the main steps of our more common wonder metal sheet metal processing technology? Perfect, the main steps of wonder metal sheet metal processing include: sheet metal processing drawing design, laser processing or (CNC stamping), bending, welding forming, electrostatic spraying or (liquid paint), and finally packaging and shipping.