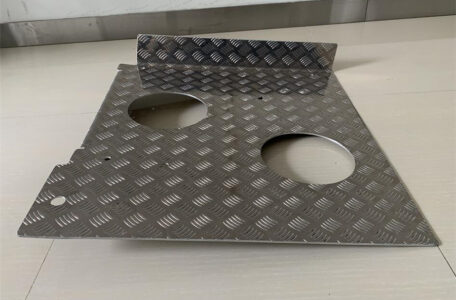

The surface texture process refers to the forging, scratching, grinding, corrosion and othe laser cutting china processes that produce texture effects on the surface of the stainless steel sheet.

Blog

What are the cutting methods of steel pipes, have you understood?

Water cutting: Water jet technology, also known as water jet or water cutting technology, is a real cold cutting. It is a high-energy water flow generated by ordinary water pressurized by a pressurizing system (portable water cutting system can reach 40Mpa~50Mpa), and then passes through a very fine sand nozzle (Φ0.1-0.35mm) at a speed of nearly one kilometer per second Read more

Let’s take a look at the relevant knowledge of tube cutting in metal laser processing

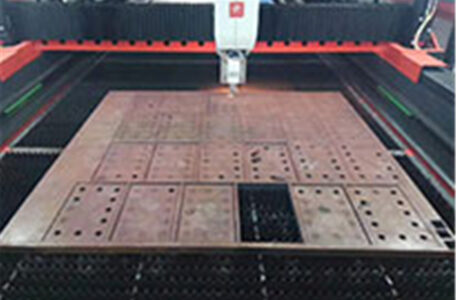

Laser technology is especially suitable for the processing of various metal pipes. Compared with traditional cutting methods such as manual sawing, sawing, roll extrusion, grinding wheel cutting, and gas welding cutting, traditional pipe cutting methods are too advanced in terms of accuracy and processing efficiency. Therefore, the application of laser processing technology in metal pipe processing is very extensive. Laser Read more

Follow the manufacturers to see laser cutting of various pipes, with fast cutting speed and high processing accuracy!

Discuss the current situation and future development of laser cutting pipe processing

What are the key technologies for laser cutting pipe processing?

Light guide focusing system In laser cutting equipment, the role of the light guide system is to guide the light beam output by the laser generator to the cutting head that focuses the light path. For laser cutting tubes, in order to obtain high-quality slits, the focused spot diameter and power of the focused beam are small, which makes the Read more

Do you know the seven advantages of the automatic laser cutting pipe processing machine?

As an advanced pipe cutting technology, laser cutting technology has been widely accepted. Laser cutting china pipe processing is widely used in fitness equipment, construction machinery, household manufacturing and other industries. In different application scenarios, there are many shapes of pipes.

What benefits does laser cutting pipe processing bring to pipe processing enterprises?

In order to maintain the competitiveness of my country’s pipe processing technology, laser processing has become indispensable. As a professional manufacturer of laser cutting pipe processing equipment, Co-Creation Laser always follows the needs of users in the research and development of laser pipe cutting machines. The laser tube cutting machine can help tube cutting users to achieve quantitative production needs Read more

What are the applications of laser technology in laser cutting pipe processing

With the advent of the era of intelligent manufacturing, various industries have higher and higher requirements for laser cutting pipe processing quality and craftsmanship. The traditional laser cutting pipe processing technology is not only inefficient, but also the cutting effect is very rough, which is easy to cause a lot of pipe waste. The use of advanced laser processing technology Read more

Learn about the characteristics and advantages of laser pipe cutting machine and process comparison

In order to maintain the competitiveness of my country’s stainless steel plate laser cutting pipe processing technology, stainless steel plate laser cutting processing has become indispensable. As a professional pipe laser cutting equipment manufacturer, Wandan Laser has always followed the needs of users in the research and development of laser automatic pipe cutting machines. The laser automatic pipe cutting machine Read more